Multihead Scale Weigher Packing machine suitable for packing screw, nuts, bolts, fasteners, plastic parts, pills, toy parts etc.

Multihead Weigher Packing Machine for Fastener Hardware Screws Bolts Nails Furniture Fittings

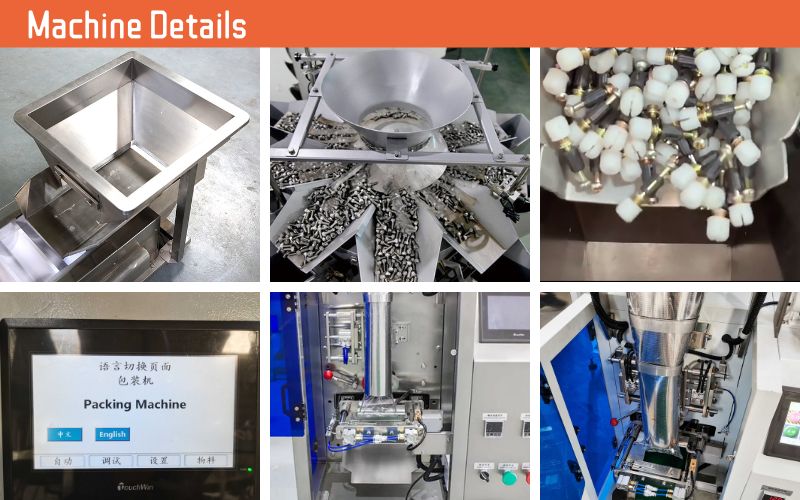

Multihead Weigher Packing Machine

1. Hardware: Found in hardware stores, construction, and manufacturing for items like screws, nuts, bolts, washers, and similar hardware.

2. Electronic Components: Used in electronics to package components like resistors, capacitors, diodes, and connectors.

3. Pharmaceutical and Medical Devices: Employed in pharmaceutical and medical device manufacturing for small items like tablets, capsules, syringes, vials, and other medical components.

4. Food and Beverages: Beneficial in the food industry for packaging small items like candies, nuts, bolts, and other snacks.

5. Cosmetics and Personal Care Products: Utilized in the cosmetics and personal care industry for packaging items like nail polish bottles, lipsticks, perfume samples, and skincare products.

6. Stationery and Office Supplies: Used in stationery manufacturing for packaging items like paper clips, staples, pushpins, rubber bands, and other small office supplies.

Packing Process

1. Product Input: The raw material or product to be packed is introduced into the weigher packing machine. This can be done manually by operators or through an automated feeding system such as a conveyor belt

2.Weighing: The weigher packing machine is equipped with weighing scales that measure the weight of the product. The machine is programmed to achieve the desired weight for each package.

3.Dispensing: Once the desired weight is determined, the weigher packing machine dispenses the product into individual packaging units.

4.Bag Sealing: Once the product is filled into the pouch, the machine proceeds to seal the bag. The top of the bag is sealed horizontally, creating a closed pouch.

5.Optional Features: Some weigher pouch packing machines may include additional features like gas flushing (to displace nitrogen with an inert gas) or vacuum sealing (to remove air from the pouch) for specific applications such as food packaging.

6.Bag Cutting and Separation: After the pouch is sealed, the machine cuts the pouch from the continuous tube or sheet of film. The cutting mechanism can be a rotary knife, a reciprocating blade, or other cutting mechanisms depending on the machine design.

7.Bag Discharge: The finished pouches are discharged from the weigher pouch packing machine. They can be collected in bins, trays, or conveyed to downstream processes such as cartoning, case packing, or palletizing, depending on the specific production setup.

Machine Parameters

Machine model DM-420LS

Packing speed 10-60 bags/min

Filling range Max. 1kg

Bag length 40-200 mm

Bag width 50-200 mm

Bag type pillow bag, back side seal bag

Film material Heat Sealable PE film and laminated Film, such as PE/PET, PE/AL/PET, BOPP, LDPE, etc.

Film thickness 0.05-0.13mm

Film max film width 320 mm

Machine voltage220V, 50Hz/60Hz

Contact: Ada

Phone: 86 15217651852

E-mail: [email protected]

Whatsapp:008615217651852

Add: Nanhai District, Foshan,Guangdong, China

We chat